Views: 0 Author: Site Editor Publish Time: 2022-05-26 Origin: Site

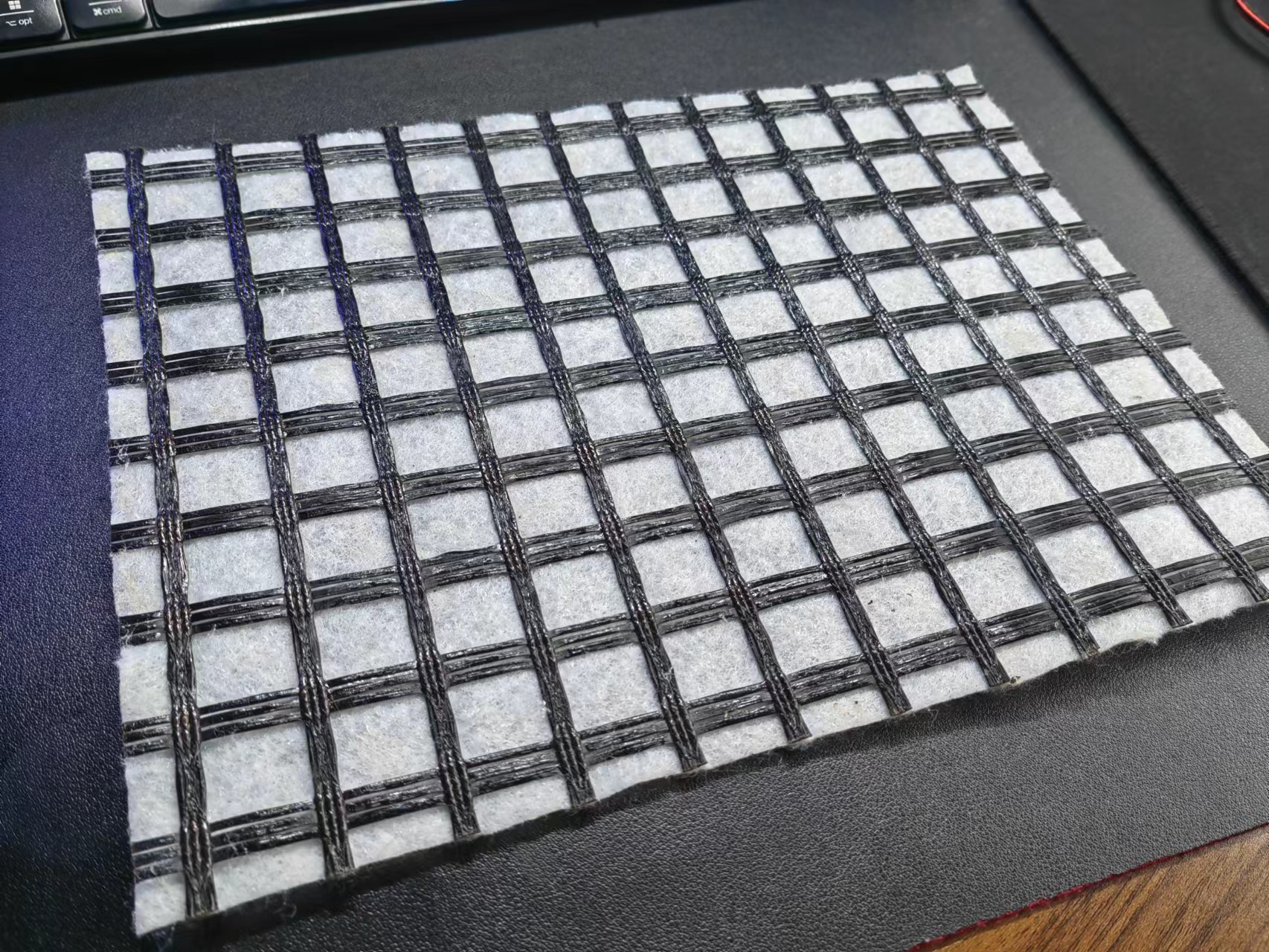

The commonly used Fiberglass Geogrid has two types with self-adhesive and without self-adhesive. The one with self-adhesive can be directly laid on the leveled base layer, and the one without self-adhesive is usually fixed by nails.

What should be paid attention to the Fiberglass Geogrid construction?

What are the steps to use Fiberglass Geogrid?

How does Fiberglass Geogrid work against low temperature shrinkage and cracking?

Only Fiberglass Geogrid can be used on the asphalt pavement, and other grids are used on the roadbed. Fiberglass Geogrid50KN is used more often. Of course, it also depends on the design standards of this road. The construction site of Fiberglass Geogrid: It is required to be compacted, flat, horizontal, and clear of spikes and protrusions.

1) When laying Fiberglass Geogrid, first accurately release the subgrade slope line. In order to ensure the width of the subgrade, each side is widened by 0.5m. After the dried base soil is leveled, it is statically pressed twice with a 25T vibratory roller, and then 50T Shake the pressure four times, and level the uneven places manually.

(2) Pave the 0.3m thick medium (coarse) sand, and after manual and mechanical leveling, the 25T vibratory roller is statically pressed twice.

(3) The bottom surface of the Fiberglass Geogrid should be flat and dense when laying. Generally, it should be laid flat, straightened, not overlapped, curled or kinked. Two adjacent geogrids should be overlapped by 0.2m, and the Fiberglass Geogrid should be horizontally aligned along the roadbed. The overlapped part is interspersed and connected with No. 8 iron wire every 1 meter, and is fixed to the ground with U-shaped nails every 1.5-2m on the laid grid.

Asphalt roads in severe cold areas, the surface temperature in winter is close to the air temperature. Under such temperature conditions, the asphalt concrete shrinks when cold, resulting in tensile stress. When the tensile stress exceeds the tensile strength of asphalt concrete, cracks will occur, and cracks will occur in the places where the cracks are concentrated, forming diseases. From the perspective of the causes of cracks, how to make the strength of asphalt concrete resist tensile stress is the key to solving the problem.

The application of Fiberglass Geogrid in the asphalt overlay greatly improves the tensile strength of asphalt concrete, which can resist large tensile stress without causing damage. In addition, even if cracks are generated in a local area, the stress at the place where the crack occurs is too concentrated, but it gradually disappears through the transmission of the Fiberglass Geogrid, and the crack will no longer develop into a crack. When selecting Fiberglass Geogrid, in addition to its performance indicators should meet the specifications in the above table, special attention should be paid to ensure that its width is not less than 1.5m, so that it has enough cross-sectional area to fully dissipate the cracks when it is used as an interlayer to control reflection cracks. Energy; At the same time, the mesh size should be 0.5 to 1.0 times the maximum particle size of the upper asphalt surface material, which will help achieve the best shear adhesiveness and promote aggregate interlocking and restriction.

Feicheng Lianyi Plastic Co., Ltd., which has been established for over ten years, focuses on the production of Fiberglass Geogrids. Here, you can find the Fiberglass Geogrids you need.